Technology Exchange

What are the applications of RFID technology in warehouse logistics management?

Warehousing is the inventory control link in the logistics and supply chain. With the gradual improvement of warehousing logistics management in recent years, warehouses are no longer just warehouses for storing goods. Inventory cost is one of the main supply chain costs. Therefore, managing inventory, reducing inventory, and controlling inventory costs have become the main tasks of warehousing to reduce the total cost of the supply chain under the framework of the supply chain. The use of RFID warehousing logistics management tags with RFID handhelds and warehousing management systems can realize intelligent warehousing and logistics management.

Daily warehousing management includes: semi-finished products processing, packaging and packaging equipment management, finished products ready to be shipped, finished products in and out of warehouse, location planning, production pull, low inventory, order breakdown, inventory, and defective products in and out of warehouse, etc.;

In the actual application link, the integrated management of the warehousing supply chain is realized through the application of modern management technology and scientific and technological means, which can realize the integrated operation of the supply chain, and software technology, Internet technology, automatic sorting technology, light guide The application of advanced scientific and technological means and equipment such as sorting, RFID, and voice control technology provides conditions for improving storage efficiency.

Management and Application of RFID Technology in Intelligent Sorting

The "automated sorting" solution based on RFID technology adopts more advanced automatic identification technology. Compared with traditional sorting systems, it has a lower error rate, is not affected by the direction of goods placement, and has great penetration Some substances read and store more material information and better scalability. Using RFID technology, the RFID reading and writing device is installed on the key node of the conveying line, which can automatically realize the tracking and management of package information. Automatically record the process and time of the goods being transported, which plays an important role in increasing the conveying speed, reducing sending errors, and losing goods.

Application of RFID technology in visual logistics management

All aspects of logistics realize the visualization of logistics information, including the visualization of logistics resource information, logistics demand information, logistics process, logistics status, logistics control and logistics environment. Logistics visualization aims at logistics information, and its premise is the digitalization of logistics.

So, what advantages can the application of RFID intelligent warehouse management bring?

The use of RFID technology as the key technology in the warehouse management system can significantly enhance the technical level of warehouse and logistics management, and enterprises can obtain a good image. In the future, they can effectively avoid and reduce repeated investment in enterprise informatization upgrades.

(1) RFID warehousing logistics management system can realize the visual management of real-time warehouse data in management, and truly realize the synchronization of physical logistics and data flow.

(2) Realizing the electronicization of pallets and loading and unloading points, realizing the rapid entry and exit of goods, effectively completing the management and distribution, realizing the positioning of the goods and quick retrieval.

RFID technology identification does not require manual intervention, is non-contact, fast collection, strong anti-interference ability, can also identify high-speed moving objects, and can simultaneously identify RFID electronic tags bound to multiple items. RFID electronic tags have the characteristics of multiple styles, small size, large information capacity, strong durability, reusability, high confidentiality, and easy portability. They are widely used in applications such as RFID intelligent warehouse management, anti-counterfeiting traceability, and inventory.

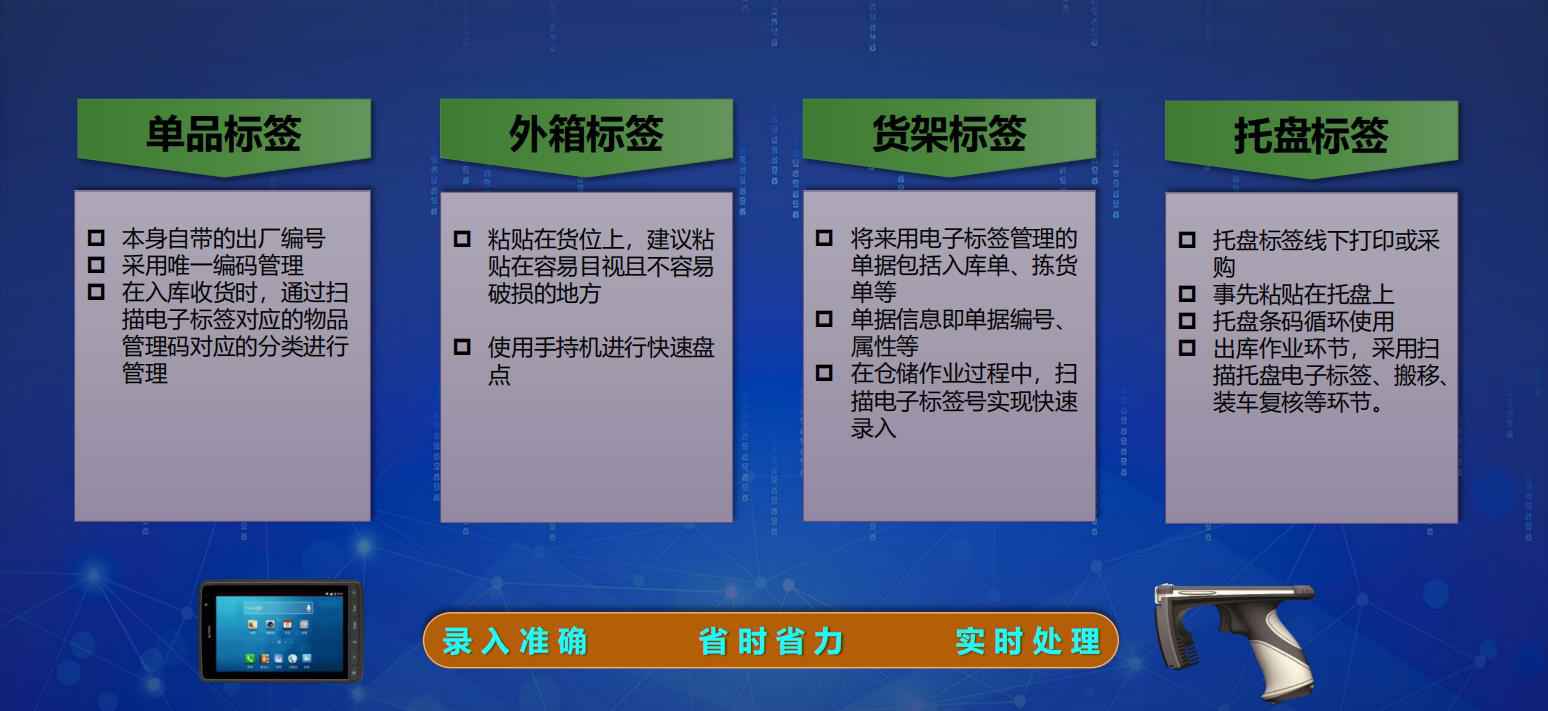

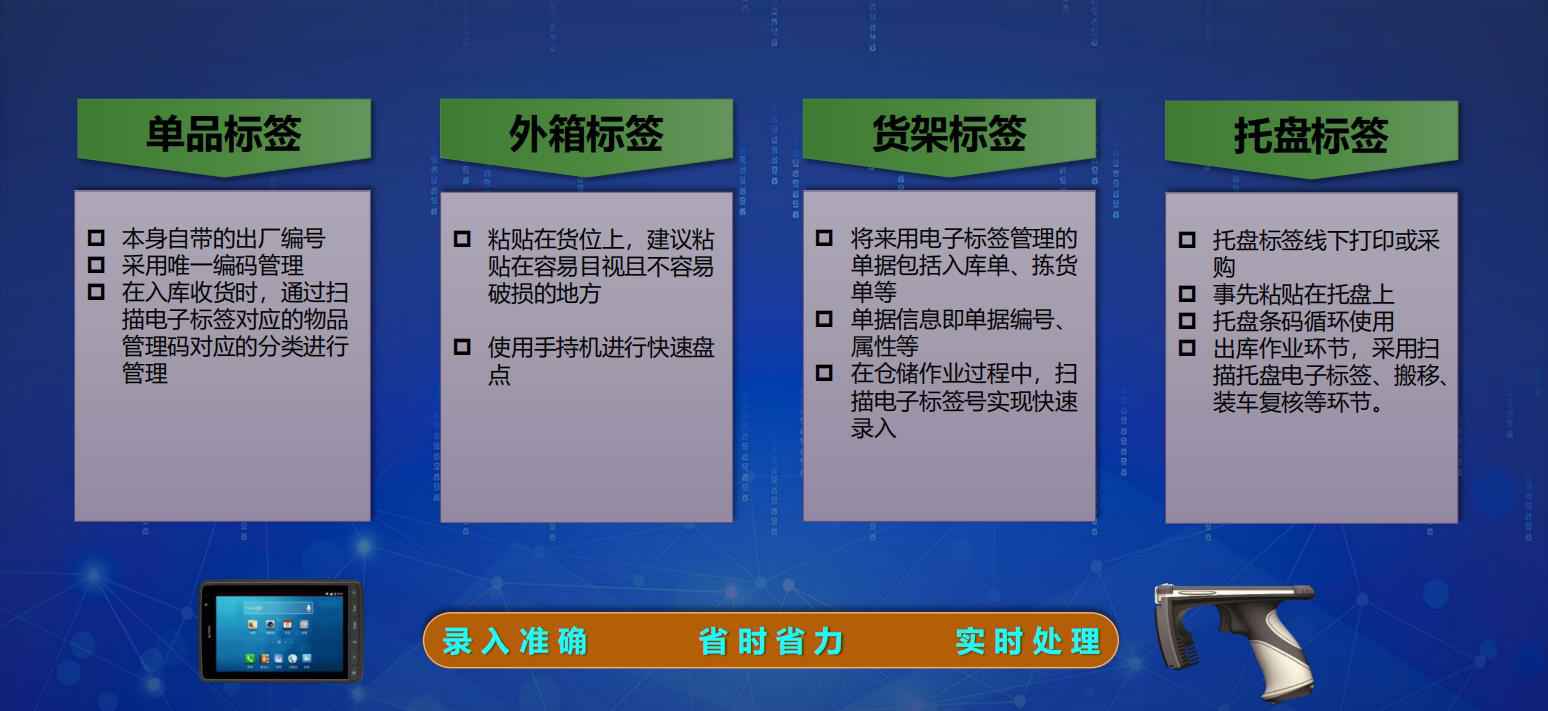

The RFID warehousing logistics management system consists of RFID electronic label issuance and labeling, warehouse management, allocation and shifting, inventory counting and additional functions. Let the application for outbound goods, the identification of outbound goods, and the downloading of outbound records be implemented quickly. The warehousing management system includes location allocation setting, unloading product identification, and warehousing record management. As the application of RFID technology becomes more and more extensive, the supply chain and warehousing logistics management fields effectively solve the problems of input/output of various business operation data in the supply chain, control and tracking of business processes, and reduction of error rates. For more RFID warehousing logistics management tags, RFID anti-counterfeiting tags, NFC tags and other related technical exchanges, please pay attention to the technology exchanges with core IoT.

Daily warehousing management includes: semi-finished products processing, packaging and packaging equipment management, finished products ready to be shipped, finished products in and out of warehouse, location planning, production pull, low inventory, order breakdown, inventory, and defective products in and out of warehouse, etc.;

In the actual application link, the integrated management of the warehousing supply chain is realized through the application of modern management technology and scientific and technological means, which can realize the integrated operation of the supply chain, and software technology, Internet technology, automatic sorting technology, light guide The application of advanced scientific and technological means and equipment such as sorting, RFID, and voice control technology provides conditions for improving storage efficiency.

Management and Application of RFID Technology in Intelligent Sorting

The "automated sorting" solution based on RFID technology adopts more advanced automatic identification technology. Compared with traditional sorting systems, it has a lower error rate, is not affected by the direction of goods placement, and has great penetration Some substances read and store more material information and better scalability. Using RFID technology, the RFID reading and writing device is installed on the key node of the conveying line, which can automatically realize the tracking and management of package information. Automatically record the process and time of the goods being transported, which plays an important role in increasing the conveying speed, reducing sending errors, and losing goods.

Application of RFID technology in visual logistics management

All aspects of logistics realize the visualization of logistics information, including the visualization of logistics resource information, logistics demand information, logistics process, logistics status, logistics control and logistics environment. Logistics visualization aims at logistics information, and its premise is the digitalization of logistics.

So, what advantages can the application of RFID intelligent warehouse management bring?

The use of RFID technology as the key technology in the warehouse management system can significantly enhance the technical level of warehouse and logistics management, and enterprises can obtain a good image. In the future, they can effectively avoid and reduce repeated investment in enterprise informatization upgrades.

(1) RFID warehousing logistics management system can realize the visual management of real-time warehouse data in management, and truly realize the synchronization of physical logistics and data flow.

(2) Realizing the electronicization of pallets and loading and unloading points, realizing the rapid entry and exit of goods, effectively completing the management and distribution, realizing the positioning of the goods and quick retrieval.

RFID technology identification does not require manual intervention, is non-contact, fast collection, strong anti-interference ability, can also identify high-speed moving objects, and can simultaneously identify RFID electronic tags bound to multiple items. RFID electronic tags have the characteristics of multiple styles, small size, large information capacity, strong durability, reusability, high confidentiality, and easy portability. They are widely used in applications such as RFID intelligent warehouse management, anti-counterfeiting traceability, and inventory.

The RFID warehousing logistics management system consists of RFID electronic label issuance and labeling, warehouse management, allocation and shifting, inventory counting and additional functions. Let the application for outbound goods, the identification of outbound goods, and the downloading of outbound records be implemented quickly. The warehousing management system includes location allocation setting, unloading product identification, and warehousing record management. As the application of RFID technology becomes more and more extensive, the supply chain and warehousing logistics management fields effectively solve the problems of input/output of various business operation data in the supply chain, control and tracking of business processes, and reduction of error rates. For more RFID warehousing logistics management tags, RFID anti-counterfeiting tags, NFC tags and other related technical exchanges, please pay attention to the technology exchanges with core IoT.

上一篇:Analysis on the application and solution of RFID smart anti-counterfeiting label 下一篇:RFID dangerous goods transportation management plan

Related news

- Do you know read-only RFID tags2022-05-16

- What are the applications of RF2021-11-10

- Do you know about RFID anti-cou2022-01-20

- Analysis on the application and2021-10-29

- Analysis on the precautions for2021-08-07

News

contact us

contact information

E-mail:

Address:Building 2, Longhua Semiconductor Industrial Park, No. 1310 Guangguan Road, Guanlan Street, Longhua District, Shenzhen

Scan code and wechat

Scan code and wechat